氧化铝生产赤泥分离与洗涤工序仿真工艺流程简介

| 2018年11月28日 00:09:51 来源:冶金系 作者:admin 录入:admin |

赤泥分离与洗涤

Clarification and washing of red mud /Proses klarifikasi dan pencucian lumpur merah

一、工艺简介(Brief introduction of process / Pengenalan singkat proses)

1.目的

赤泥分离洗涤的目的是将来自溶出工序的稀释矿浆中的溶液和赤泥分开,溶液送入叶滤工序,赤泥进入洗涤流程以回收赤泥附液带走的有用成分——碱和氧化铝,洗水送往稀释槽。

1. Objective / Tujuan

The purpose of the red mud clarification and washing process is to separate the solution and the red mud in diluted slurry from digestion process, the solution is sent to the leaf filtration process, and the red mud enters the washing process to recover useful components taken away by the red mud such as alkali and alumina. The wash water is sent to be used in dilution tank.

Tujuan dari proses klarifikasi dan pencucian adalah untuk memisahkan larutan dari lumpur merah di dalam diluted slurry keluaran dari digestion process. Larutan yang telah dipisahkan kemudian dikirim ke proses pressured leaf filtration, sedangkan lumpur merah masuk ke proses washing untuk memperoleh kembali komponen yang bermanfaat seperti alkali dan alumina. Air pencucian digunakan kembali di dalam dilution tank.

2.工艺流程简介

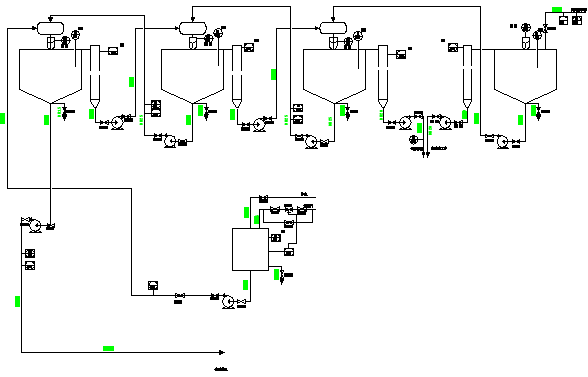

从溶出工序稀释槽来的稀释液进分离沉降槽,溢流进入叶滤工序精制成精液后送晶种分解工序,底流依次进入四级洗涤沉降槽,末次沉降槽出来的底流用隔膜泵打入赤泥过滤工序,一次沉降槽溢流则去溶出工序的稀释槽。在所有洗涤沉降槽中,洗液都是下一个沉降槽的溢流,末次洗涤沉降槽的洗液则是热水。图3-1为4级逆流分离洗涤工艺流程图。

2.Brief introduction of process flow / Pengenalan singkat aliran proses

The diluents from the dilution tank in the digestion process enter the clarification and settling tank. The overflow of the clarification tank enters the leaf filtration process, and is refined into a fine liquid then sent to precipitation process; the underflow enters four stage washing and settling tank. Underflow from the last settling tank is pumped into the red mud filtration process by a diaphragm pump. The overflow of the primary settling tank will go to dilution tank of the digestion process. In all of the washing settling tanks, the washing liquid is the overflow from the next settling tank, and the washing liquid of the last settling tank is hot water. Fig 3-1 is the 4-stage countercurrent clarification and washing process.

Larutan dari dilution tank dalam proses digestion masuk clarification and settling tank. Overflow dari clarification tank yang terpisah masuk ke proses pressured leaf filtration untuk memperoleh fine liquid yang akan dikirim ke proses precipitation; underflow dari clarification tank masuk ke empat setlling tank untuk dilakukan washing secara bergantian. Underflow dari setlling tank ke-4 dipompa dengan pompa diafragma ke proses red mud filtration; sedangkan Overflow setlling tank ke-1 masuk ke dilution tank di digestion process. Di dalam washing settling tanks, cairan pencuci merupakan overflow dari settling tank berikutnya, sedangkan cairan pencuci untuk settling tank terakhir adalah air panas. Gambar 3-1 diagram alir dari 4-stage countercurrent clarification and washing process.

图3-1 四级逆流分离洗涤工艺流程图

Fig 3-1. 4 stage countercurrent separation and washing process flow chart

Gambar 3-1. diagram alir dari 4-stage countercurrent clarification and washing process

打印 | 打印 |  收藏 | 阅读:2325 收藏 | 阅读:2325

|