氧化铝生产粗液叶滤工序仿真工艺流程简介

| 2018年11月27日 22:52:54 来源:冶金系 作者:admin 录入:admin |

粗液叶滤

Thick liquid filtration / Crude Liquid Pressure Leaf Filtration

一、工艺简介(Brief introduction of process / Pengenalan singkat proses)

1.目的

从沉降工序来的粗液在叶滤机中过滤,合格的滤液(精液)送往分解工序。

1. Objective / Tujuan

The crude liquid from clarification process is filtered in the leaf filter, and the qualified filtrate (semen) is sent to the precipitation process.

Crude liquid dari proses klarifikasi disaring di dalam leaf filter, dan filtrat yang memenuhi syarat (fine liquid) dikirim ke proses presipitasi.

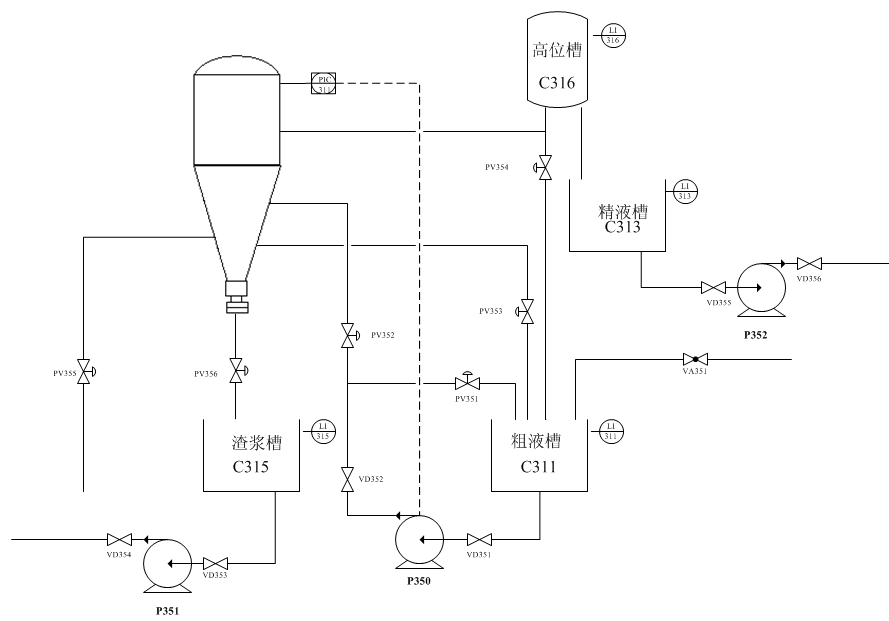

2.工艺流程简介

从赤泥分离洗涤工艺分离溢流槽(C301A)过来的溶液进入本工艺中的粗液槽(C311),由粗液泵(P350)打入叶滤机(Y311)中,经过叶滤机过滤后,精液从叶滤机顶部出来经过高位槽(C316)溢流进入精液槽(C313),渣浆从叶滤机底部排至渣浆槽(C315)。图4-1为粗液叶滤工序流程图。

2.Brief introduction of process flow / Pengenalan singkat dari aliran proses

The solution from the overflow tank (C301A) in red mud clarification and washing process is introduced into the crude tank (C311), pumped by the crude liquid pump (P350) into the pressure leaf filter (Y311). After filtering through the leaf filter, the filtrate from high level drum (C316) at the top of the pressure leaf filter overflow into the filtrate tank (C313), and the slurry is discharged from the bottom of the pressure leaf filter to the slurry tank(C315). Figure 4-1 is a flow chart of the crude liquid pressure leaf filtration process.

Larutan dari overflow tank (C301A) dalam proses klarifikasi dan pencucian lumpur merah, dimasukkan ke dalam crude tank (C311), dipompa dengan crude liquid pump (P350) ke dalam pressure leaf filter (Y311). Setelah melalui proses filtrasi dalam pressure leaf filter, filtrat dari high level drum (C316) pada bagian atas pressure leaf filter akan meluap ke filtrate tank (C313), sedangkan slurry dibuang dari bagian bawah pressure leaf filter ke slurry tank(C315)

图4-1 粗液叶滤工序流程图

Fig 4-1.Flow chart of crude liquid pressure leaf filtration

Gambar 4-1. diagram alir dari crude liquid pressure leaf filtration

打印 | 打印 |  收藏 | 阅读:1138 收藏 | 阅读:1138

|